Mn18Cr18N

Mn18Cr18N, Mn18Cr18N高氮奥氏体不锈钢由于其优良的力学性能和耐腐蚀性能, 是制造大型发电机护环的首选材料

Mn18Cr18N Datasheet

Mn18Cr18N High manganese non-magnetic hard wearing steel: Chemical composition

Mn18Cr18N High manganese non-magnetic hard wearing steel - mechanical properties

| Heat treatment | Min | Max | Similar | Note |

|---|

| Heat treatment | Min | Max | Similar | Note |

|---|

| Heat treatment | Min | Max | Similar | Note |

|---|

| Heat treatment | Min | Max | Similar | Note |

|---|

| Heat treatment | Min | Max | Similar | Note |

|---|

| Heat treatment | Type | Min | Max | Similar | Note |

|---|

Mn18Cr18N高氮奥氏体不锈钢由于其优良的力学性能和耐腐蚀性能, 是制造大型发电机护环的首选材料. 护环用钢采用冷变形方法强化, 其中600 MW护环室温屈服强度要求达到1200 MPa, 而1000 MW护环室温屈服强度要求达到1300 MPa以上.

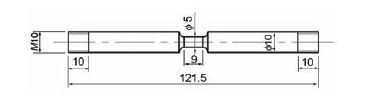

图1 压缩拉伸试样示意图

Fig.1 Schematic of specimen for compression-tensile test (unit: mm, ϕ—diameter, M—diameter of thread)

图2 Mn18Cr18N奥氏体不锈钢原始组织

Fig.2 Original microstructure of Mn18Cr18N austenite stainless steel

图3 Mn18Cr18N 奥氏体不锈钢压缩变形前后试样的XRD谱

Fig.3 XRD spectra of Mn18Cr18N austenite stainless steel specimens at 0 and 40% compression reduction

图4 Mn18Cr18N奥氏体不锈钢经不同压缩变形量后的压缩拉伸真应力-应变曲线

Fig.4 Compression-tensile true stress-strain curves of Mn18Cr18N austenite stainless steel under different compressive reductions

图5 Mn18Cr18N奥氏体不锈钢压缩拉伸的典型应变和应力值随压缩量的变化

Fig.5 Typical compression-tensile strain (a) and stress (b) variation with compression reductions of Mn18Cr18N austenite stainless steel

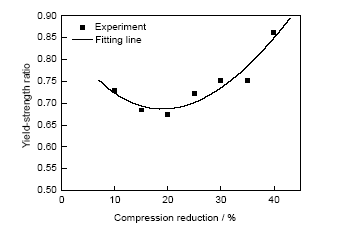

图6 Mn18Cr18N奥氏体不锈钢后续拉伸屈强比随压缩量的变化

Fig.6 Yield-strength ratio variation with compression reduction of Mn18Cr18N austenite stainless steel

图9 Mn18Cr18N奥氏体不锈钢经不同压缩变形量后拉伸至断裂的断口形貌SEM像

Fig.9 Fracture SEM images of Mn18Cr18N austenite stainless steel for compression-tensile test at the compression reductions of 0% (a), 15% (b), 25% (c), 30% (d), 35% (e) and 40% (f)

图10 Mn18Cr18N奥氏体不锈钢不同压缩量下微观组织的OM像

Fig.10 OM images of microstructures in Mn18Cr18N austenite stainless steel for compression reductions of 15% (a), 25% (b), 35% (c) and 40% (d)

图11 Mn18Cr18N奥氏体不锈钢断口纵截面组织的OM像

Fig.11 OM images of fracture microstructure (longitudinal section) of Mn18Cr18N austenite stainless steel for compression-tensile test at the compression reductions of 15% (a), 25% (b), 35% (c) and 40% (d)

图12 Mn18Cr18N-high-manganese-non-magnetic-hard-wearing-steel-61-7963" target="_self" title="Mn18Cr18N">Mn18Cr18N奥氏体不锈钢不同加载状态下的TEM像

Fig.12 TEM images of Mn18Cr18N austenite stainless steel under different deformation conditions(a) 15% compressive reduction (b) tensile to fracture after 15% compressive reduction(c) 35% compressive reduction (d) tensile to fracture after 35% compressive reduction

Mn18Cr18N High manganese non-magnetic hard wearing steel delivers

- Bars, hot-rolled bars, hot-rolled round bars, cold-drawn round bars, hexagonal bars, octagonal bars, hot-rolled flat bars, cold-drawn flat bars, special-shaped steel

- Hot cold rolled strip and coils

- Hot Cold Rolled Plate Sheet

- Hot rolled and Cold drawn Shaped

- Hot rolled and cold drawn wire

- Forgings and forged bars